Lab

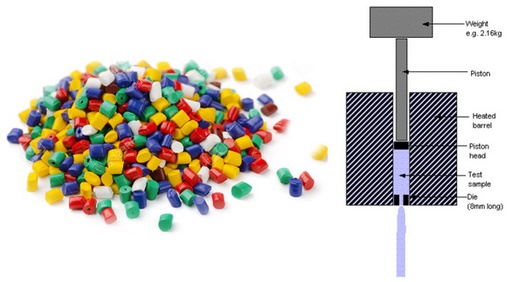

Melt Flow Index (MFI)

The fluidity of molten plastic granules under certain temperature and pressure conditions is g / 10 min. It is designated as.

The fluidity of molten plastic granules under certain temperature and pressure conditions is g / 10 min. It is designated as.

Fluidity is one of the parameters which is critical in the processing and molding of the product and therefore its control is very important. The MFI (ISO 1133) test (Melt Flow Index), which is the fluidity index, is performed with the Melt Indexer test device.

In this test, the material is melted with temperature and a certain load is applied on it and it is determined how much material flows through a capillary tube within 10 minutes under this load.

Charpy Notched Impact Strength

Under certain test conditions, the impact strength of the relevant plastic is determined by determining the amount of energy absorbed per notched cross-sectional area as kj / m2 in the sample broken by the impact made on the surface where the notch is located in the horizontal test rod.

It is also possible to determine the hardness with our falling ball test equipment where we can determine the breaking or cracking energy of a ball of a certain weight released from a certain height on a stationary part, and the Shore durometer where the surface hardness of the materials is measured.

Izod Notched Impact Strength

The Izod Notched Impact Strength test, which can be measured in the same type of device as the Charpy Notched Impact Strength test, is tested by placing it vertically instead of horizontally in contrast to the Charpy Notched Impact Strength test under certain test conditions.

The impact strength of the relevant plastic is determined by determining the amount of energy absorbed per cross-sectional area in the notch as kj / m2 in the sample broken by the impact made on the surface of the notch on the vertical test rod.

Tensile Tensile Test

The elongation amount and% elongation of the stretched sample pulled with a certain speed and force, the maximum applied tensile strength is determined.

The elongation amount and% elongation of the stretched sample pulled with a certain speed and force, the maximum applied tensile strength is determined.

In order to determine this standard, which examines the strength of the material under load, the tensile rods printed in accordance with ISO 527 norms in the universal mechanical pulling device are squeezed with two clamps at certain and constant speeds and values such as tensile strength, yield strength, elongation at break and tensile modulus can be obtained that can provide information about the strength of the product. .

To give a brief example of the meanings of these values, the tensile strength will be high but the elongation value at break will be low in highly filled-reinforced products, which means the material is strong but fragile. Conversely, products with low tensile strength but high elongation (eg unfilled-unreinforced elastomers) are considered soft and weak materials.

Three Point Bend Test

With the load at a certain speed applied to the sample from three points, the elastic strength, the elongation at the breaking point, the% elongation and the maximum force applied to the specific area are determined.

Density Test

The weight of the granular plastic material is measured first in air and then in a certain alcohol, and the density of the material is tested.

certain alcohol, and the density of the material is tested.

In addition to the density value determined at laboratory temperature with the help of a density meter (ISO 1183), the filler / reinforcement ratio of the product can be determined in accordance with the ISO 3451 standard in an ash furnace.

The filling / reinforcement ratio of the material affects all properties, especially the mechanical properties.

Hardness Test

The relative hardness of the plastic is determined by measuring the depth of the needle immersed in the plastic sample with a certain force on the fixed stand.

Hardness is measured according to Shore D for hard plastics and Shore A for soft plastics.

Additive Measuring Set / Ash Test

The amount of plastic in the sample, which is kept in the oven at a certain temperature for a certain period of time, is removed from the environment and brought to a fixed weight. The amount of ash is calculated as% and the amount and type of additive in the material is determined.

In the ash furnace, the filler / reinforcement ratio of the product can be determined according to the ISO 3451 standard. The filling / reinforcement ratio of the material affects all properties, especially the mechanical properties.

Color Harmony Determination

The color of the sample given under specified fixed conditions is defined according to the Lab system. Thus, it is ensured that the colored sample that will come from every field of the industry is produced exactly in the desired color and target.

English

English

Türkçe

Türkçe عربى

عربى